Hizmetler

What is a steel construction structure?

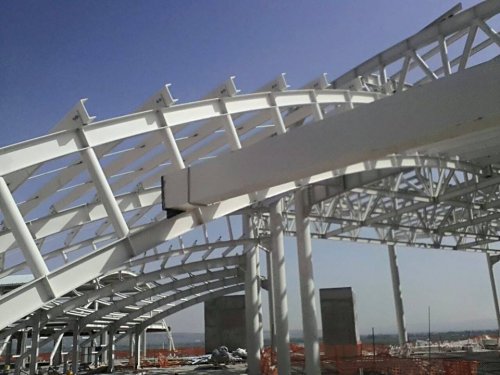

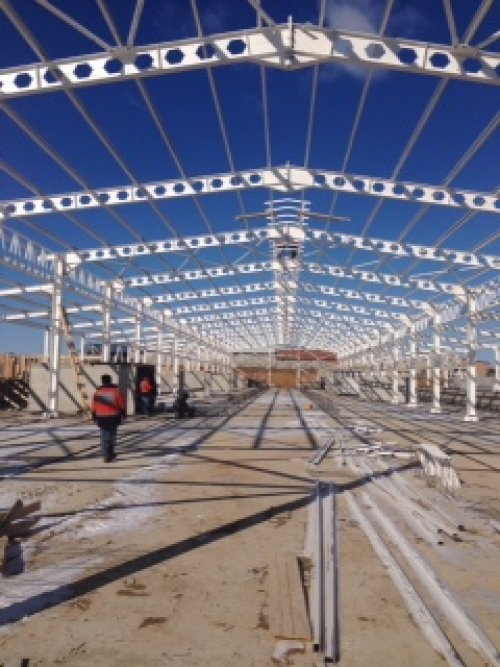

A steel structure system with broad openings and heights, where all carrying systems are made of steel, being preferred in geographical regions particularly under earthquake threat, and usually used in steel construction factory buildings, steel construction sheds, steel construction sports facilities, steel construction warehouse and steel construction workshops.

A steel structure system with broad openings and heights, where all carrying systems are made of steel, being preferred in geographical regions particularly under earthquake threat, and usually used in steel construction factory buildings, steel construction sheds, steel construction sports facilities, steel construction warehouse and steel construction workshops.

Large majority of urbanization in our country is intensified in the 1st and 2nd degree earthquake

regions. However, the preference of steel construction structure systems was in the past quite less.

Steel constructions possess quite superior mechanical features, static capacities and application

facility compared to other carrying systems. Steel construction is a steel structure system, which is

becoming rapidly popular, since they are rapid, safe and economical and have certain standards.

Technical Features of Steel Structures

What types of steel construction structures are available?

Steel construction structures are divided in two categories i.e. heavy steel and light steel construction

structures. Examples for heavy steel structures we can state factory buildings with large openings

and hoists; and prefabricated workshops and warehouse structures can be stated under light steel

structures.

Steel construction structures are divided in two categories as insulated and uninsulated.

Polyurethane panels or rock-wool panels used at the walls and roofs of insulated buildings ensure

heat and noise insulation. Reason for preference of uninsulated steel buildings is economic.

Where are steel construction structures used?

Steel construction structures are usually used in buildings i.e. steel factory buildings, steel industry

structures, aircraft sheds, sports facilities, steel construction sheds, steel construction workshops,

steel construction warehouses.

What are the advantages of steel construction structures?

They are lesser exposed to earthquake loads, because they are light; they are stable, ensure labor

and time saving during manufacturing and assembling, different construction systems are applicable,

they are rapid, they can be dismantled and re-assembled severed times, they are hardwearing, steel

is 100% recyclable, and independent from how many time this process is made, it does not lose its

features, and is not harmful to the environment.

Steel Construction Structures (Prismatic Structures)

Steel construction workshop, steel construction warehouse structures, steel construction prismatic

structure systems can be custom manufactured as insulated and uninsulated.

Technical data of steel constructions:

Structures are manufactured considering 1st degree earthquake conditions. Wind speed is 102

km/hour (h:0.8 m) TS498, snow load 80 kg/m2. They are manufactured in the factory and can be

assembled on ground concrete prepared previously by the consignee; and field assembled structures

may be dismantled at any time and reassembled at another place.

Steel construction dimensions:

Structure width 10 m single opening – column height

h:4-5-6 m is possible. The building length is extendable as desires in multitudes of 2.5m. Provided

that a block width of 10 m is not exceeded, double, triple, quadruple, quintuplet blocks can be made.

Steel construction carrying system:

Consists of NPI column, solid webbed steel trusses and purlins, and wind connections are provided.

Connections are ensured with steel bolts and nuts.

Roof and Façade Covering: 0.50 mm corrugated galvanized sheet plates are fixed with galvanized

cladding and sealed nails.

Doors: Manufactured bolted in dimensions of 350*350 cm. (A personnel service door of 900

mm*2000 is available over the door.)

Paint: Entire steel system is painted with anti-rust paint and one layer oil-paint.

Industrial type and social context steel construction structures

Factory, showroom structures

Technical Data of Steel Buildings: Structures are manufactured considering 1st degree earthquake

conditions. Wind speed 102 km/hour (h:0-8 m), TS498 snow load 80 kg/m²

Dimensions: Structure width 12-30 m (single opening), column height 4-12 m, building length can be

made in desired length and column axis distance may be 3-6 m.

Carrying System: Depending on structure’s width, the column may be box shaped made of 2 NPU

beams, solid webbed trusses, webbing system or complete fragmented systems may be used.

Connections are ensured with steel bolts and nuts. If desired also crane system may be made. They

can be manufactured either insulated or uninsulated. Structures may have single stories or two or

three stories.

DIFFERENCES BETWEEN STEEL CARCASS AND PREFABRICATED STRUCTURES

Depending on the increased housing demand in the last years caused a huge increase of the housing

prices. Housing prices have reached balloon prices quite above their original values. However are the

priced still not drawn by the housing sellers to normal prices or it is not desired to do so.

This forced the citizen with limited budget to look out for other solutions. Different structure types

used in other countries started to draw our attention. Despite to that such are referred under various

names, they are bringing a range of advantages thanks to their basic features i.e. rapid manufacture,

being detached, their safety and price advantage.

These are referred as prefabricated houses, steel houses or ready-made houses. They represent both

similar as well as differentiating features.

Steel construction houses have steel columns and beams. Such houses, which carrying parts are

made of steel, have concrete walls, whereby different materials i.e. steel may be used. Steel houses

are usually not moved from the place of their installation. There are no story restrictions regarding

steel houses; they may be built with stories as desires, even the highest buildings in the world are

built as steel construction.

Prefabricated houses have not separate carrying material. The carrying duty is assumed by the walls.

Walls may be made of sheet, plastic or other materials. They are generally constructed as 1 or 2 story

buildings. They are not suitable to be built as multi-story structures.

Both structure types are rapidly constructed story-by-story compared to reinforced concrete

buildings. They are more resistant against earthquakes. Both structures have quite more affordable

prices compared to reinforced concrete buildings.